RAILS TO BLACK ROCK A blog about the construction of a 5.5mm scale model of a fictitious Ffestiniog Railway branch line to Black Rock Sands via Borth y gest. This was a railway that was proposed in real life but never built. Although a model railway, the model has an equal focus on the distinctive architecture of North Wales.The picture above gives an overall view of the area of the village being modelled.

Monday 27 January 2014

Now there are a few followers of this blog I thought I'd include a few more photos of my previous layout 'Dulas' to give an idea of the kind of scenery I am aiming for. I really like simple understated scenes where the railway is almost incidental... Above is Maespoeth shed. A scene no longer possible with the building of the carriage shed in the field in the foreground. The trees look a bit crude by todays standards but the buildings still convey the mood of the place well.

Aberllefenni Station. A very simple building and a single siding to run the train around on. No one could ever give a definitive answer to how the back of the building was constructed. I surmised it was probably timber.

Pant Perthog curve. One of the joys of modelling a real location is the feedback you get from the public. One lady who had lived next to the school told us about a day when pigs escaped and were found wandering the line by the school, a detail we added later. No doubt we will learn of lots of little stories which can be added to the Borth y gest scene.

Having tested the chassis using the white metal parts with Romford pinpoint bearings, the tender rolled like a boat in a storm! So the white metal parts were removed and the alternative etched axle components used. In fairness they look much better than the white metal parts.

The tender now runs with minimal wobble. The wheels were place in a mini drill and burnished with a fibre glass pen. A piece of copper clad strip has been used to make the pick up assembly. The pick ups are made from phosphor bronze wire. I have used this in all my previous chassis as it has good springing qualities and produces minimum friction on the wheels. The pick up assembly is held in place by a brass bolt which allows very fine adjustment and easy future repair.

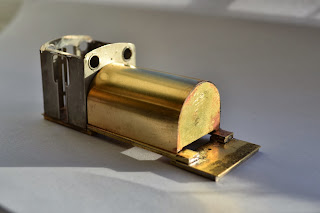

The finished chassis. The motor is much larger than the one supplied with the original kit and there is plenty of room for a fly wheel to be installed in the next few weeks. The wires will be routed down through the rear of the chassis to connect up permanently with the additional pick up wires from the tender.

Having tested it with a temporary connection, the chassis and tender run incredibly reliably over point work. This will be an absolute essential to make the layout work as intended. As on Dulas, locos will have to perform complicated shunting manoeuvres over a limited track plan with no 'hands on' help. On Dulas eighteen separate shunts were required to run trains around at the Aberlleffeni terminus and we could often achieve this for several hours without a nudge from a hand. Shunting is a long way off however but time spent achieving reliability now should pay dividends later on.

Another comparison of the original white metal chassis and the larger scratch built body. The brake gear still needs modifying before fitting.

Sunday 19 January 2014

Having looked at lots of photographs I came to the conclusion that despite carefully calculating the sizes from a 7mm drawing, the tender was too tall! so it has been taken apart and filed down by 1.5mm. A new floor had to be made, but it all went back together fine, it's just taken rather a lot of time!

I have used scrap white metal to fill the coal space, this will be covered with something more convincing later on. The added weight will hopefully help with current collection. I have a sheet of Archer's Rivets to give lots of surface detail. I can use the vacuum pipe from the original kit. I have etched brass brake shoes to add to the under frame.

Sunday 5 January 2014

The tender chassis will have a removable pick up assembly to allow for easy future adjustments. The problem is how to fit this but also to include brake details. The brakes will come from the etch for the shorter wheel base small tender.

The tender will fixed to the loco by a coupling bar which can be unbolted if needed. The power collection wires will be clipped under the coupling bar.

A few more photos of the houses which will form the backdrop to the layout...

In recent years the houses have been painted a range of pastel shades. In the period I am modelling they will have more muted shades for the walls, but lots of green, red, brown window frames. Apart from the three storey row at the front of the layout which has exposed stone walls the rest are rendered which will make construction a little easier. As so many windows have been modernised I will need to decide on the style that would have been present in the 1920s and 30s...

Saturday 4 January 2014

Today has been spent making the scratch built body for the large tender. The measurements were taken from a 7mm drawing and scaled down to 5.5mm scale. The tender is much bigger than the tender supplied with the MSM kit, there was a moment when i placed it next to the loco when I thought I must have calculated the dimensions incorrectly, however a quick look at photos of Welsh Pony displayed with a large tender this summer confirmed that the heights were accurate.

The wires sticking out of the cab will be routed below the footplate to the tender. The tender will have pick ups on all wheels to improve the engines reliability. The original cast chassis for the tender has been used but Romford pin point bearings have been inserted.

Here the difference in the size of the tenders is clear.

The wires sticking out of the cab will be routed below the footplate to the tender. The tender will have pick ups on all wheels to improve the engines reliability. The original cast chassis for the tender has been used but Romford pin point bearings have been inserted.

Here the difference in the size of the tenders is clear.

Friday 3 January 2014

The Chassis is now up and running after a few frustrating hours working out why it was growling rather than purring. It turned out that the rather expensive grease used in the gearbox was causing friction rather than reducing it; once replaced with a tiny drop of oil the chassis ran smoothly.

Thoughts then turned to the body. The first task was to build a new footplate and running plate. This is needed to use the etch for the larger cab and to allow for the tank being 6" longer; in the model this equates to an additional 3mm. All in all a lot of work for a small change to the length of the loco!. The footplate was made of two layers of brass sweated together, this proved to be quite tricky and required a powerful soldering iron to get the layers to bond properly. The result, after a great deal of filing is a very sturdy footplate which matches the rest of the etch very well.

Thoughts then turned to the body. The first task was to build a new footplate and running plate. This is needed to use the etch for the larger cab and to allow for the tank being 6" longer; in the model this equates to an additional 3mm. All in all a lot of work for a small change to the length of the loco!. The footplate was made of two layers of brass sweated together, this proved to be quite tricky and required a powerful soldering iron to get the layers to bond properly. The result, after a great deal of filing is a very sturdy footplate which matches the rest of the etch very well.

The replacement longer tank was then made in brass. The two end profiles were made using the original as a pattern. The ends were tacked to the main tank sheet and this was gradually rolled to profile. The end result is strong and has plenty of space for ballast

The tank was finally offered up to the rest of the body. The whole assembly has noticeably different proportions to Prince or Palmerston.

Subscribe to:

Posts (Atom)